Custom Thermoforming Services

Thermoformers by Choice, Specialists by Design

Our Plastic Thermoforming Services

Partnering with experts who offer creative solutions and years of industry expertise can directly impact the successful realization of any vision. Whether you’re seeking high-production, high-speed packaging solutions or require heavy-duty, specialized plastic parts, Custom Plastic Forming is the plastic thermoforming partner you need. For more than 24 years, Custom Plastic Forming has provided the high-quality heavy- and thin-gauge thermoforming services that professionals across a broad range of industries need to keep their operations going strong.

Discover how Custom Plastic Forming can help bring your design plans to life by contacting us for a plastic thermoforming quote today!

Thermoforming VS. Injection Molding

When it comes time to bring your creative ideas to life, you’ll need a proven process to get the job done right. For your custom plastic manufacturing projects, there’s no better solution than the custom thermoforming services our North Carolina team provides:

Thermoforming

Injection Molding

Our Plastic Thermoforming Services

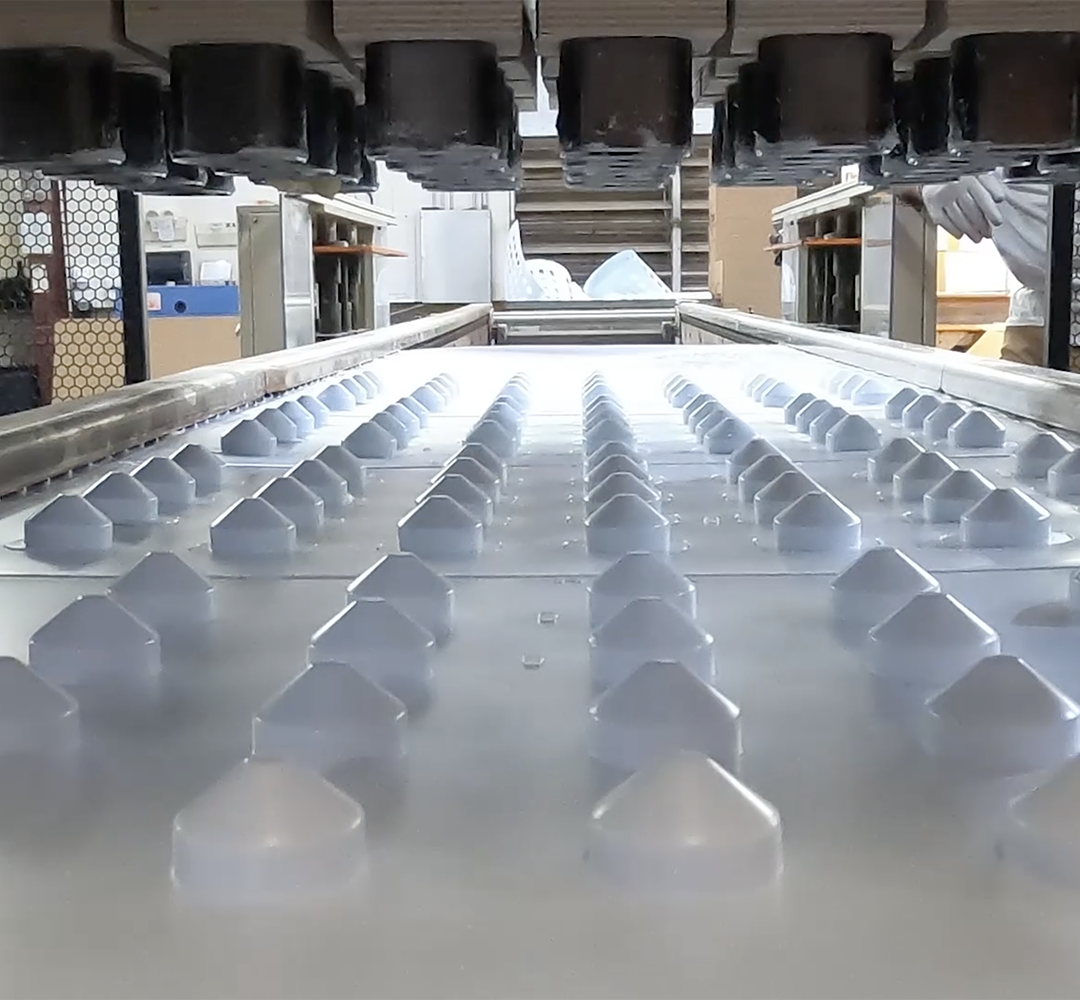

At Custom Plastic Forming, our facility utilizes equipment ranging from small single stations to mid- to large-scale, three-station rotaries. Our largest 9’ x 11’ three-station pressure former boasts a 60” draw depth capability, perfect for high-volume product creation. We are one of the only thermoformers in the industry that specializes in both thin- and heavy-gauge thermoforming, capable of handling virtually all of your plastic forming needs.

Thin-Gauge Thermoforming

Our in-line, thin-gauge thermoforming is capable of creating materials from 0.010” – 0.09” thick. Perfect for high-production thermoforming projects, our thin-gauge plastic forming solutions can be crafted from the following materials:

From disposable medical packaging to assembly line trays, there’s no thin-gauge thermoforming project too complex for our team to handle. Learn more about our thin-gauge thermoforming capabilities or request a personalized quote from our team today.

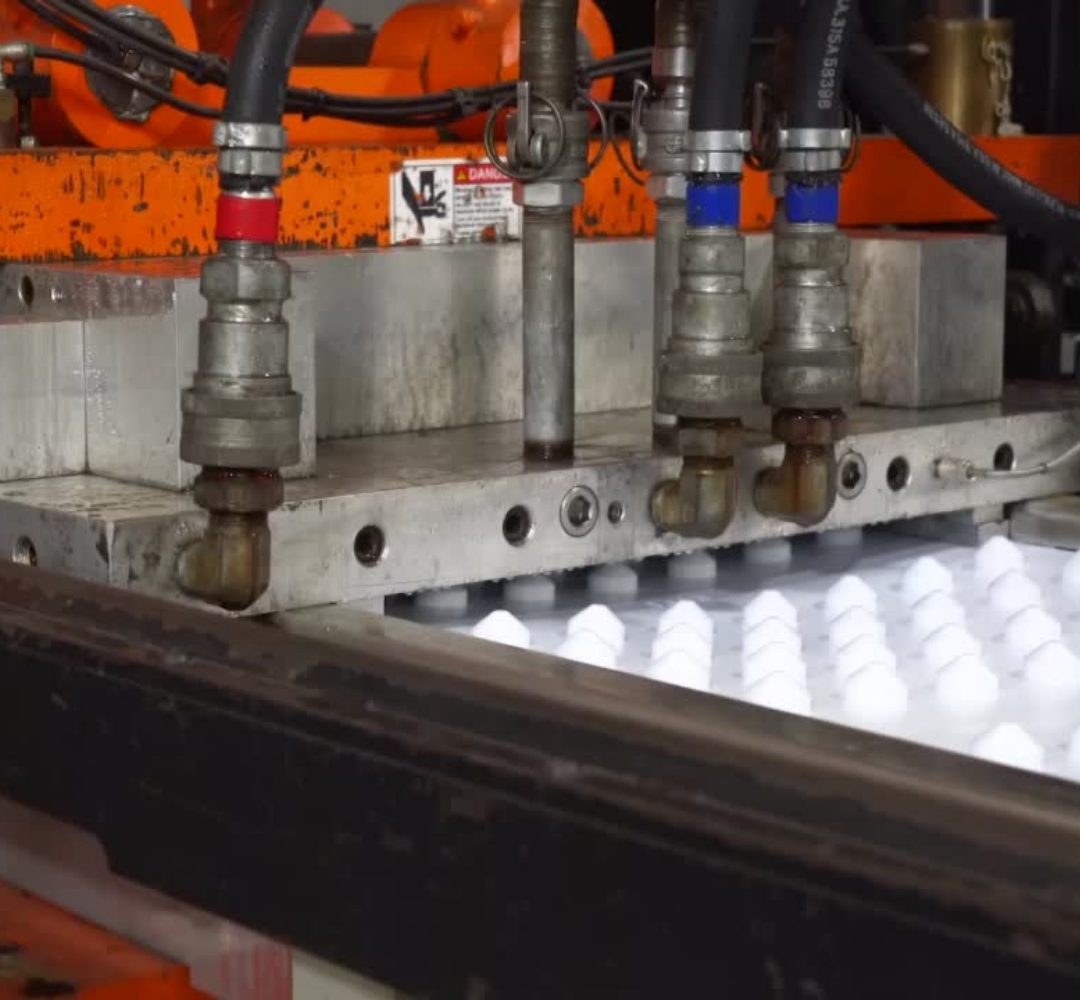

Heavy-Gauge Thermoforming

Home to one of the largest heavy-gauge thermoforming machines on this side of the Mississippi, our three-station pressure form rotary machine is capable of handling sheet sizes up to 9’ x 11’ and 0.500” thick with a max draw of 60” to create all your heavy-duty plastic components. Select from our broad range of available plastic materials to complete your heavy-gauge thermoforming project:

From automotive dunnage and medical packaging to fitness equipment and aerospace applications, our heavy-gauge thermoforming capabilities know no bounds. Discover more about our heavy-gauge thermoforming process or request a prompt, personalized quote today!

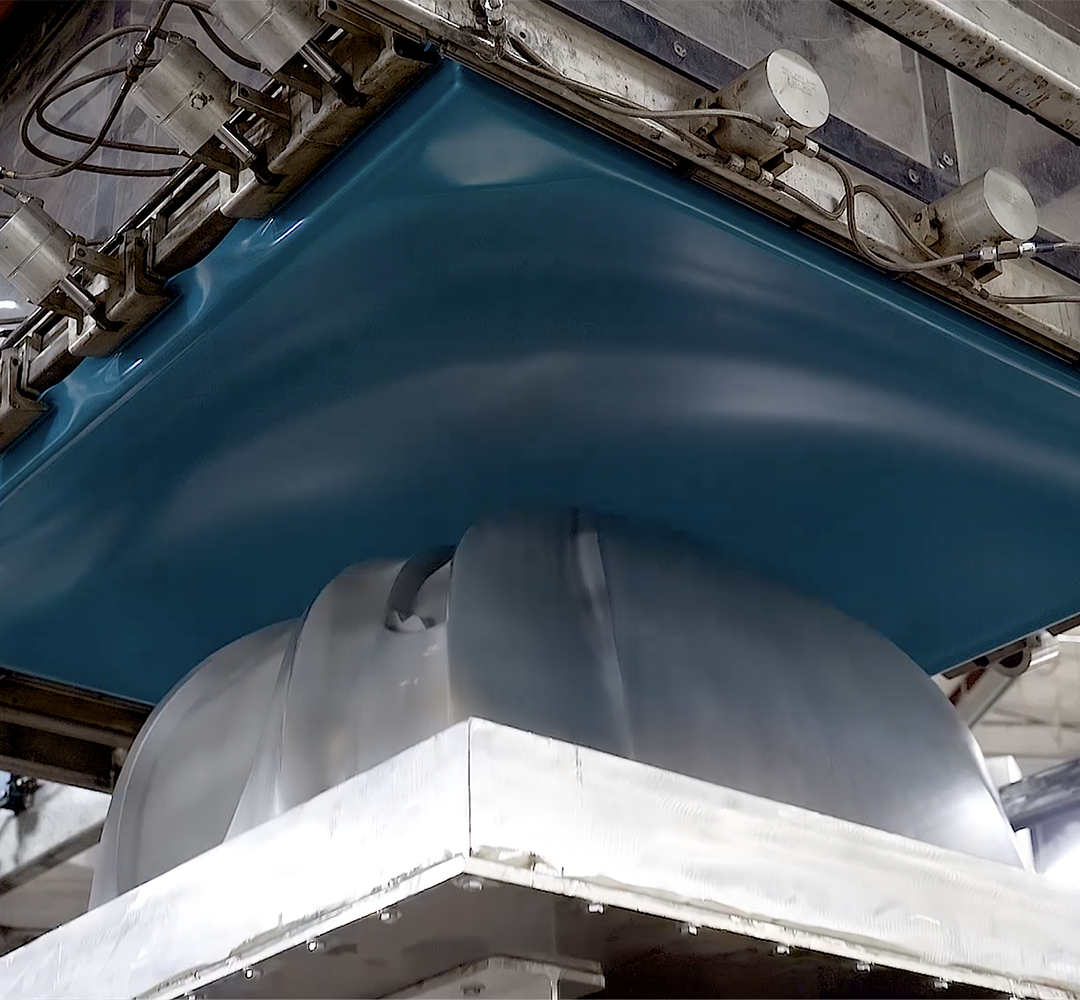

Pressure Forming

In addition to our thin- and heavy-gauge thermoforming capabilities, our team produces some of the most detailed plastic products using our unparalleled pressure forming equipment. By adding air pressure to the outside surface of the pliable plastic, in addition to the vacuum applied during forming, the result is a crisper, more defined final product. This is an excellent way to achieve an injection-molded aesthetic without the associated tooling costs or size limitations. Learn more about our pressure forming capabilities and submit your custom quote request today.

Why Custom Plastic Forming’s Thermoforming Services?

Request A Quote!

No matter the size, scope, or complexity of your plastic forming request, Custom Plastic Forming is the team you need to get the job done right. Receive a fast, free quote from our team by contacting Custom Plastic Forming online today!